The advent of 3D printing has ushered in a revolutionary era where the physical world can be digitally manifested with unprecedented precision and creativity. Originally conceived as a rapid prototyping technology, 3D printing, also known as additive manufacturing, has transcended its initial purpose. Today, it has permeated various industries, from manufacturing and healthcare to aerospace and art. At the heart of this transformative journey lies the integral role of computing technologies. This article explores the 3D printing revolution, highlighting its diverse applications and the indispensable contribution of computing in pushing the boundaries of what is possible.

The Genesis of 3D Printing

Prototyping and Beyond

The roots of 3D printing trace back to the 1980s when it was primarily utilized for rapid prototyping in industrial settings. This groundbreaking technology allowed engineers and designers to translate digital models into physical prototypes swiftly. The early stages of 3D printing were marked by limited materials and relatively simple designs.

Computing Catalyst

As computing power increased, so did the capabilities of 3D printing. The intricate algorithms and sophisticated software required to precisely control the layer-by-layer deposition of materials became feasible with advancements in computing technologies. This convergence paved the way for 3D printing to evolve from a niche prototyping tool to a disruptive force across diverse industries.

Computing in 3D Printing Processes

1. Digital Modeling and Design

The journey of a 3D-printed object begins in the digital realm. Complex computer-aided design (CAD) software allows designers to create intricate and detailed 3D models. These digital blueprints serve as the foundation for the entire 3D printing process. The efficiency and precision of modern CAD software, powered by robust computing resources, enable the creation of highly sophisticated and customized designs.

2. Slicing Algorithms

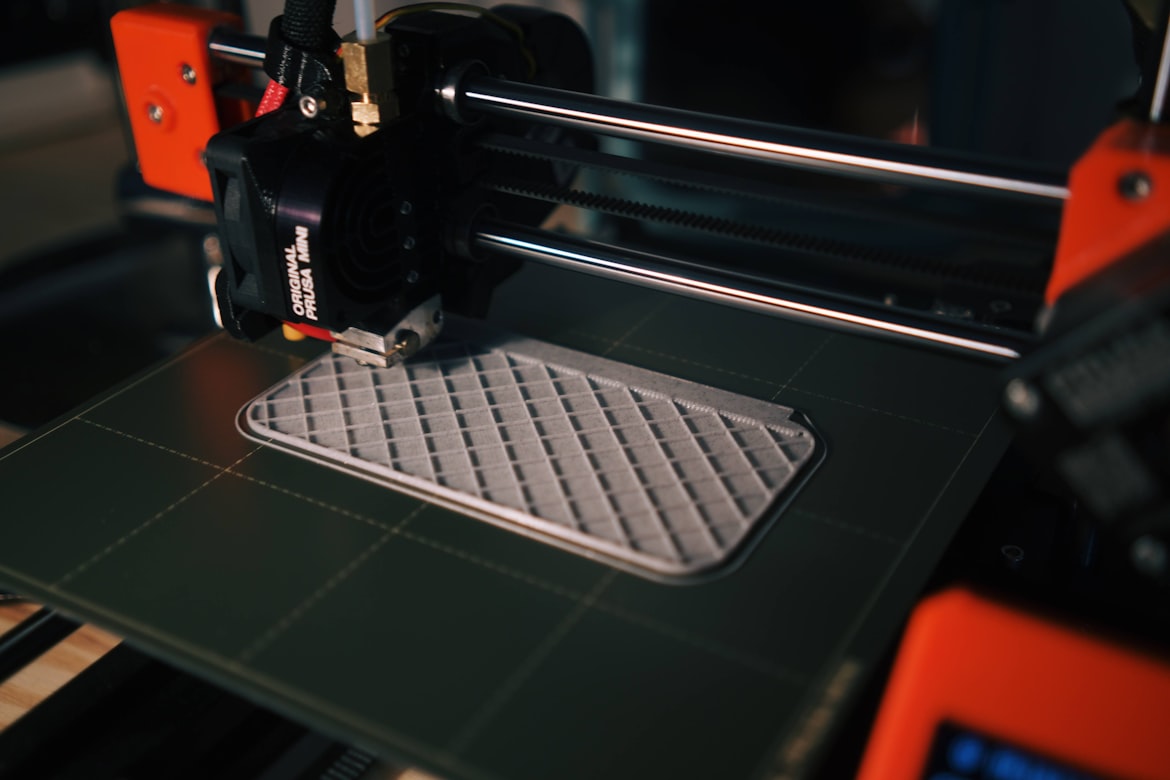

Once a digital model is created, slicing algorithms come into play. Slicing involves breaking down the 3D model into numerous thin layers, akin to the layers of a cake. Each layer represents a cross-section of the object, and these layers guide the 3D printer in the additive manufacturing process. Computing technologies ensure that the slicing process is accurate and optimized for the specific 3D printer being used.

Diverse Applications of 3D Printing

1. Manufacturing and Prototyping

While rapid prototyping remains a cornerstone of 3D printing, its applications in manufacturing have expanded significantly. Industries can now produce intricate components, customize products, and iterate designs rapidly. The ability to create prototypes on-demand accelerates product development cycles and reduces costs.

2. Medical Breakthroughs

One of the most profound impacts of 3D printing is witnessed in the field of healthcare. From patient-specific implants to prosthetics and even functional organs, 3D printing has revolutionized medical treatments. Computing technologies contribute to the precision required for creating personalized medical devices and organs, enhancing patient care and outcomes.

Computing Challenges in 3D Printing

1. Optimizing Print Parameters

The success of a 3D print relies on optimizing various parameters, including layer thickness, printing speed, and temperature control. Computing technologies aid in simulating and analyzing these parameters to achieve the desired print quality. Continuous improvements in algorithms contribute to the efficiency of the printing process.

2. Material Science and Simulation

The variety of materials used in 3D printing, from plastics and metals to bioinks, demands a nuanced understanding of material science. Computing technologies enable simulations that predict the behavior of materials during the printing process, ensuring the structural integrity and functionality of the final product.

Future Trends: Computing Horizons in 3D Printing

1. Multi-Material and Multi-Modal Printing

The future of 3D printing lies in the realm of multi-material and multi-modal capabilities. Advances in computing will play a pivotal role in orchestrating the printing of complex objects with different materials and properties. This opens avenues for creating integrated products with diverse functionalities in a single print run.

2. Generative Design and AI Integration

Generative design, powered by artificial intelligence (AI), is a promising trend in 3D printing. AI algorithms can explore countless design possibilities and optimize structures based on specific criteria. The integration of AI with 3D printing processes will usher in a new era of efficiency and creativity in design and manufacturing.

Computing’s Role in Accessibility and Innovation

1. Open-Source Communities

The accessibility of 3D printing owes much to open-source communities that share designs, software, and knowledge freely. Computing technologies facilitate collaboration within these communities, fostering innovation and democratizing the tools required for 3D printing. This collaborative spirit accelerates the evolution of the technology.

2. Educational Initiatives

3D printing is becoming an integral part of educational curricula, providing students with hands-on experience in design and manufacturing. Computing technologies enable educational initiatives by providing software tools and resources that empower students to explore their creativity and understand the principles of additive manufacturing.

Conclusion: Computing the Fabric of Innovation

The 3D printing revolution is a testament to the symbiotic relationship between computing technologies and human ingenuity. From the conceptualization of digital models to the intricacies of slicing algorithms and the optimization of print parameters, computing is the silent force propelling 3D printing into new frontiers. As we stand at the intersection of innovation and accessibility, computing continues to be the fabric woven into the very essence of the 3D printing landscape, promising a future where the boundaries